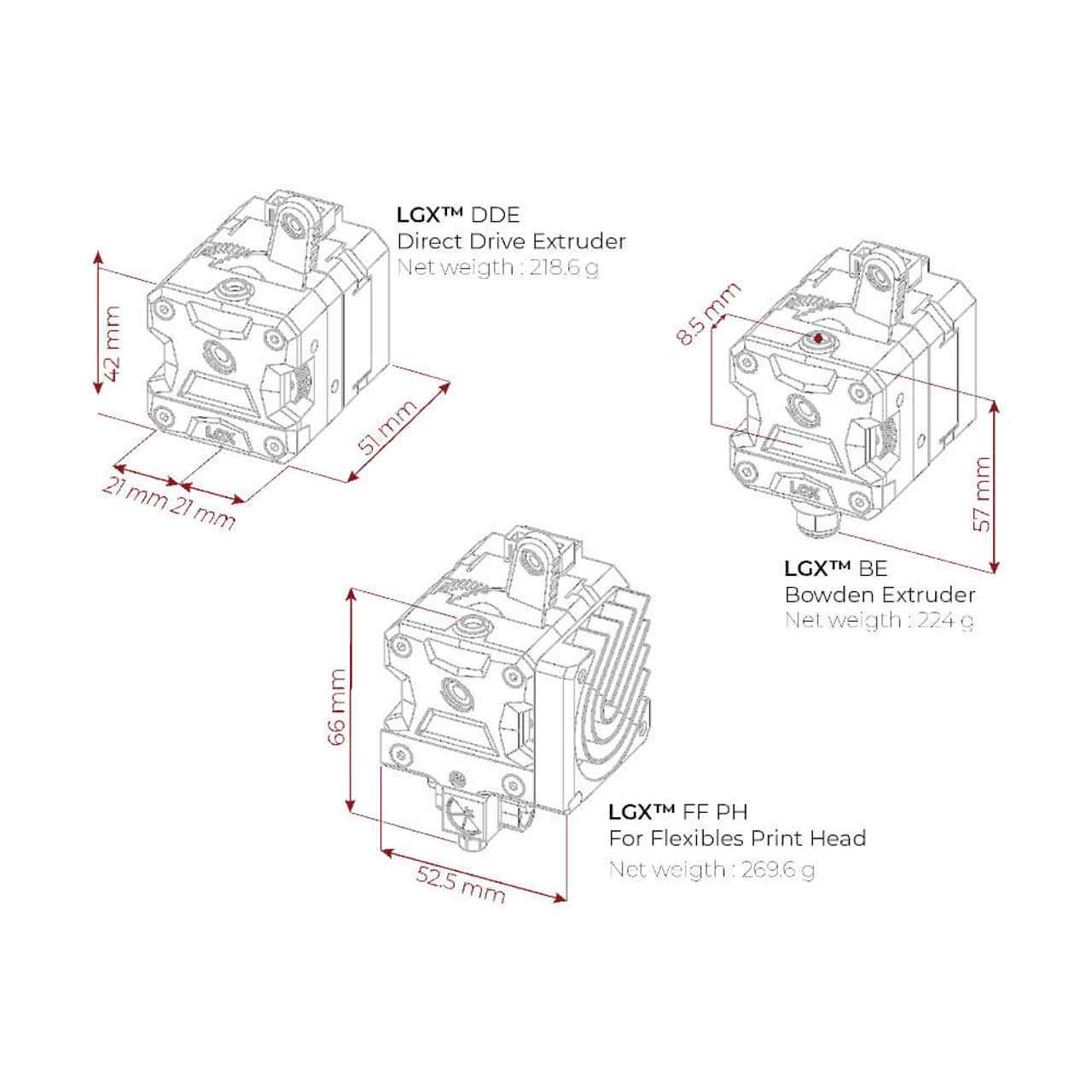

If you need to put a plate in between the stepper motor and the extruder please notice that you need longer screws, and the max supported thickness is 3mm. Preferably, you should always use the extruder attached to the stepper motor when you mount it on a printer. The housing parts are professionally printed with nylon for maximum strength and precision and higher temperature resistance. You can read more about the new features by going to Bondtech website. A small step for a greener Future, craft boxes without bleaching & no coating. Multiple mounting hole patterns, for easy and flexible setup Compact, light & symmetric design, for increased performance and compatibility Drive wheels’ maintenance windows, for easy cleaning Multi-function interface socket, for tool or application quick swap Filament pre-tension lever, for repeated results Larger drive wheels, for increased filament grip The Bondtech LGX™ Large Gears eXtruder is the first of our filament feeders using Bondtech’s new Dual Drive Technology based on larger drive gears.

#Bondtech lgx vs hemera download

#Bondtech lgx vs hemera drivers

The formula for these drivers is Vref = I * 8 * R, w here "I" is the target current value measured in A and "R" is the Sense Resistor value, which depends on what board are you using. The formula for these drivers is Vref = ( I * 2.5 ) / Imax, w here "I" is the target current value measured in A and Imax is 1.77 on regular mode and 1.2 on SilentStepSticks mode. Each type of stepper motor drivers has its own formula to calculate the required Vref to get a specific current. It helps us with setting the current output of the stepper motor driver.ĭifferent 3D printer mainboards use different stepper motor drivers. The Vref value is a voltage reference measured in VDC that can be read using a multimeter. To determine that current we rely on the Vref value. It is very hard to read the current being fed to stepper motors. Max temperature at this environment temperature can go up to 130☌ on account of the self heating.

If it is too hot, lower Vref ( click here for more information).Ĭlass B motor, rated up to 130☌. Download the stepper motor Technical Data Sheet here. !!! Important: Be vigilant regarding the stepper motor surface temperature !!! To use the LGX, run the stepper motor with currents between ~0.45 and ~0.65A: Slight chamfer inside is recommended, but not mandatory.PTFE tube should be cut straight on both ends.e-steps value recommended for the LGX is 400.

#Bondtech lgx vs hemera full

stepper motor is a 1.8 degrees motor hence 200 as full steps per rotation.The above calculation assumes the following parameters: Rotation_distance = full_steps_per_rotation * microsteps / steps_per_mm This image below shows what screws are used on the LGX, and the red ones are used to attach the stepper motor and extruder: If you need to put a plate in between the stepper motor and the extruder you will need longer screws, and the thickness of the plate must not exceed 3mm. Preferably, you should always use the extruder attached directly to the stepper motor when you mount it on a printer. !!! Please read all notes below for important installation information !!! The housing parts are professionally printed with nylon (PA 12) for maximum strength and precision and higher temperature resistance. 30mm PTFE tube to use in the Direct Drive Interface Plug.4x M3x18 mm Stud with 5mm Hex with M3x4 thread.1x Direct Drive Interface Plug (for Slice Engineering hotends).1x Bowden Interface Plug (with threaded metal push-fit).1x Custom LDO Nema17 25mm pancake stepper motor.

You can read more about the new features by clicking here.

0 kommentar(er)

0 kommentar(er)